On November 20, Meijin Hydrogen Energy Headquarters Base Phase I project, one of the 50 major projects in Beijing 2023 undertaken by China Construction Technology, held the capping ceremony of the main structure of Building 2, marking an important stage victory for the construction of the project and laying a solid foundation for the subsequent completion and delivery.

Chen Su, chairman of China Construction Technology Trade Union, Tang Shengming, Mayor of Huangcun Town, Daxing District of Beijing, Liu Qi, deputy mayor of Huangcun Town, Daxing District of Beijing, Yao Jinli, director of Shanxi Meijin Energy Co., LTD., Chairman of Meijin Hydrogen Energy, Chairman of Lioneng New Energy, Qiao Lei, general manager of Beijing Seris International Engineering Consulting Co., LTD., and Zhang Jianfei, chairman of China Construction Integration, attended the ceremony.

In his speech, Chen Su said that the successful capping of the main structure of Building 2 of the headquarters base of Meijin Hydrogen Energy is the result of the joint efforts of all teams, and expressed gratitude on behalf of Zhongjian Technology to various government departments, Meijin Hydrogen Energy Company and supervision units for their help in the construction of the project. He stressed that in the next project construction tasks, China Construction Technology will always adhere to the management consciousness of "quality is life", adhere to the business philosophy of "science and technology leadership, innovation and win-win", and work hard to ensure quality, quantity and timely delivery of high-quality projects that satisfy all parties.

On behalf of the government, Tang Shengming expressed warm congratulations to the Meijin Hydrogen Headquarters Base project and heartfelt thanks to all the comrades who participated in the construction of the project! And said that the Meijin Hydrogen energy headquarters base project is one of the important projects in China's hydrogen energy industry, to promote the development of China's hydrogen energy industry has a pivotal position. The capping of the No. 2 plant structure marks that the project has achieved phased results, and has taken a solid step for the development of China's hydrogen energy industry.

In her speech, Yao Jinli expressed her gratitude to the design unit, construction unit, supervision unit and all the personnel involved in the construction of the project. She expressed the hope that all parties will continue to carry forward the spirit of unity and cooperation, overcome difficulties, further accelerate the project construction progress, ensure that the project is completed and put into operation at an early date, and contribute to the development of China's hydrogen energy industry with a high sense of responsibility and mission.

Zhang Jianfei presided over the ceremony. Leaders from Shanxi Meijin Energy Co., LTD., Beijing Siris International Engineering Consulting Co., LTD., Zhongjian Integrated Technology Co., Ltd. and relevant personnel from Meijin Hydrogen energy Project Department attended the capping ceremony.

Green buildings practice THE two-carbon strategy

Meijin Hydrogen Energy Headquarters Base project is located in the hydrogen energy industry Demonstration Park of Huangcun Town, Daxing District, Beijing, with a total construction area of 36,000 square meters. The project will apply a number of green building technologies, such as ground source heat pump and photovoltaic building integration system, to achieve near-zero energy consumption of buildings and reduce carbon by about 63% per year. After the completion of the project, it will effectively improve the production scale and speed of carbon paper, the core technology of hydrogen fuel cells, promote the industrialization and commercialization of domestic hydrogen vehicles and hydrogen energy utilization, and help achieve the goal of "dual carbon".

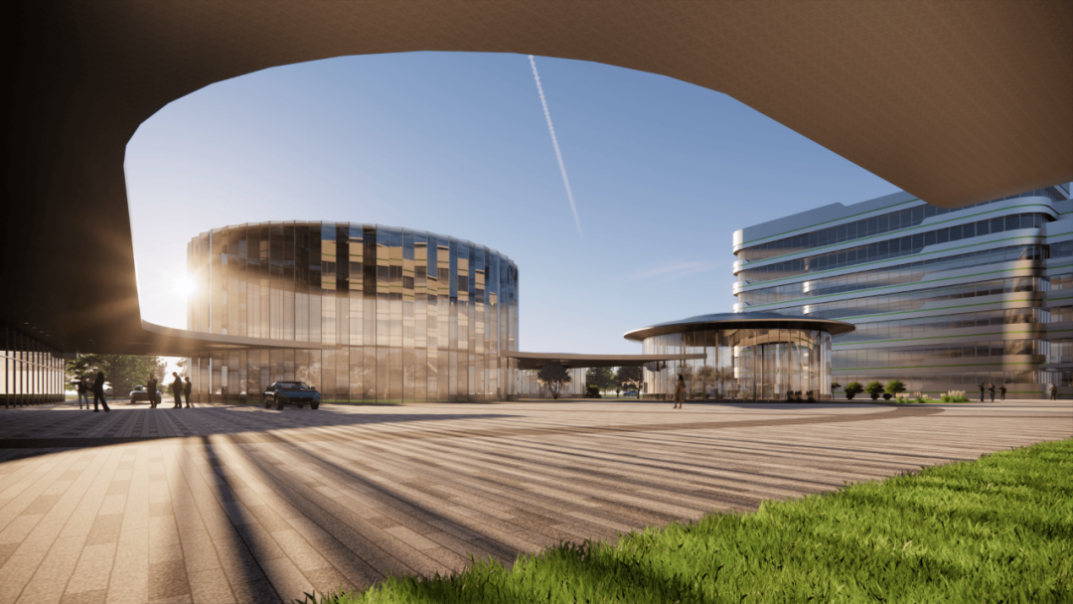

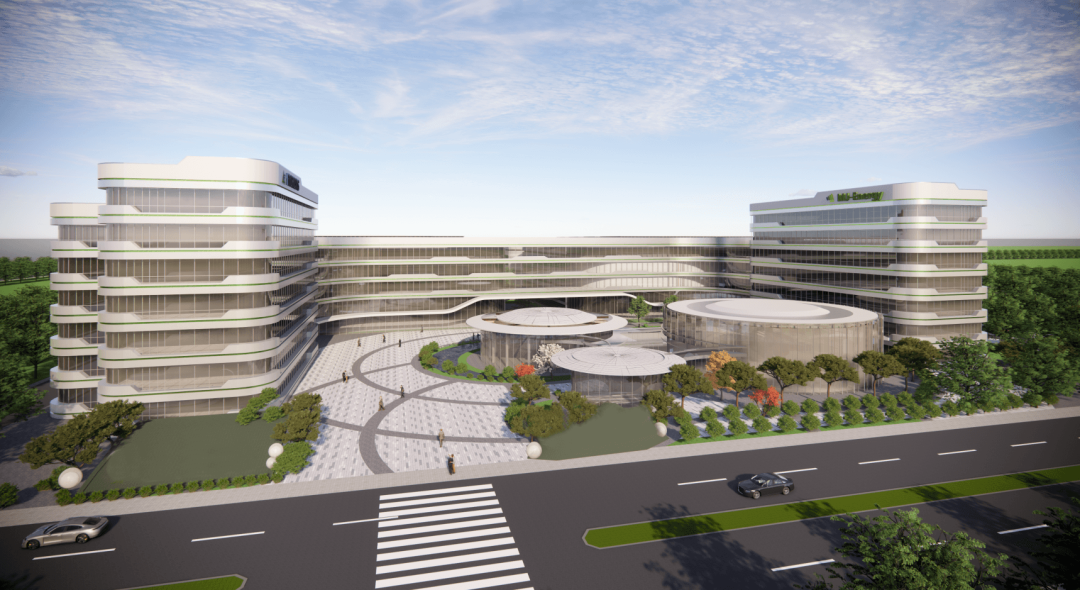

▲Renderings of Meijin Hydrogen energy project

Innovative technology promotes technological construction

Inspired by the microscopic form of hydrogen bond, the project is divided into production area, ecological area, living area, landscape area and exhibition area, forming an integrated comprehensive park with harmonious and unified ecology, life and production. The prefabricated steel-concrete composite frame structure and high-rise concrete-filled steel tube composite structure in the ten unique technology systems of China Construction Technology are adopted, and the prefabricated building intelligent construction platform independently developed by China Construction Technology is applied. Through the platform, the integrated design of digital twin buildings, electromechanical pipelines and steel beams is built to realize the effective integration of prefabricated and digital design. Record the construction data of the whole life cycle of the project, build the whole process quality and progress traceability system, form the whole process construction data integration model, and finally achieve digital delivery.

▲ Renderings of Meijin Hydrogen energy project

We are working against time to ensure high quality compliance

The project takes high-quality performance as its purpose, vigorously improves construction site control measures, overcomes difficulties such as small site and complex structure, and flexibly mobilizes on-site labor. The project began the earth-moving construction of Building 2 on May 25, completed the earthmoving excavation in 4 days, completed the pile foundation construction and ground source heat pump construction in 28 days, completed the foundation construction in 35 days, and completed the construction of the first single main structure in Building 2 in 120 days. At present, the project has successfully declared Beijing Green Safety Construction site and Beijing Structural Great Wall Cup.

Artisan quality engineering to help the development of hydrogen energy, China Construction Technology will continue to promote the efficient implementation of the Meijin project, with practical actions to help the development of hydrogen energy industry, to contribute to the realization of the dual carbon goal.

Wechat-CCISTC

Wechat-CCISTC